Polymer Market Research

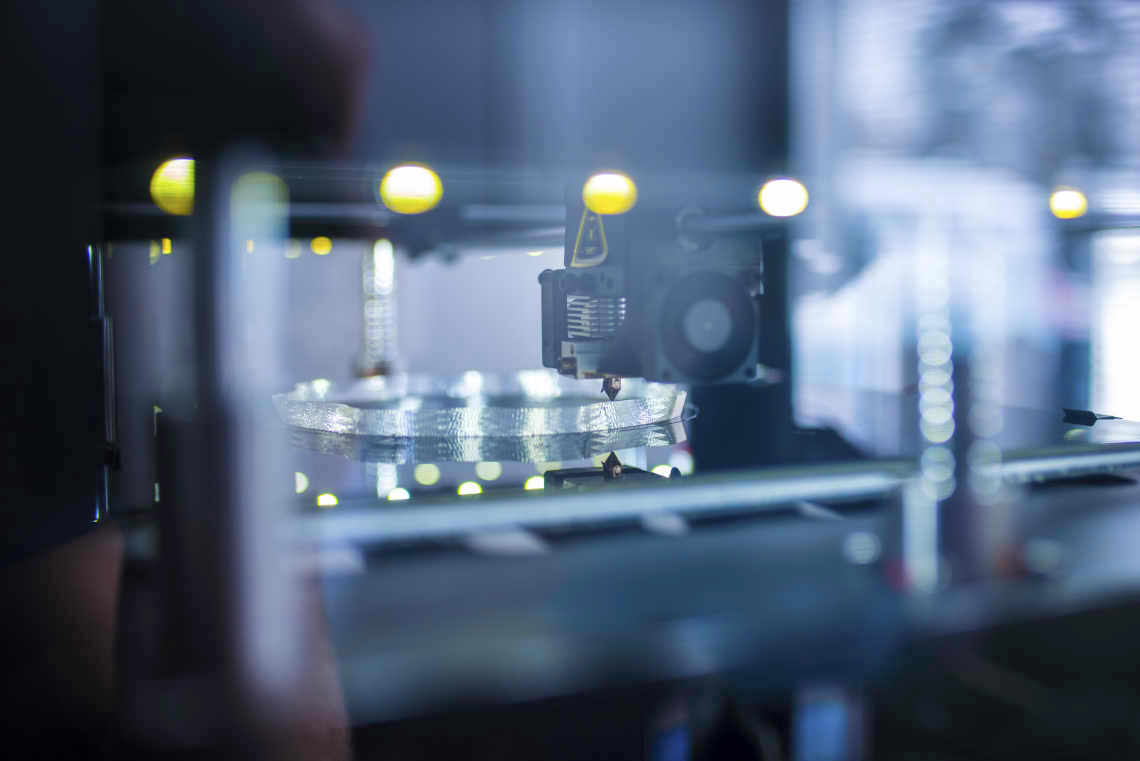

A polymer is a large molecule consisting of repeated subunits called monomers. These monomers form chemical bonds to make a long chain. Polymers can include hundreds or thousands of monomers. Their properties depend on the type and arrangement of the monomers within the chain.

Some common examples of polymers include plastics such as polyethylene, polystyrene, and PVC. Natural polymers include proteins, DNA, and cellulose. Polymers can have a wide range of physical and chemical properties. These properties include flexibility, rigidity, transparency, electrical conductivity, and thermal stability. Thus, they are helpful in various applications.

Why are Polymers Important?

Polymers are essential for a variety of reasons, including versatility. They can be designed for specific properties such as strength or flexibility. Another of their strong points is thermal stability. Electrical conductivity is yet another benefit of this wonder material.

Many polymers are also inexpensive to produce. Hence they are a cost-effective choice for a variety of applications. Polymers are often very durable and can withstand wear and tear. As a result, they are ideal for use in packaging, construction, and transportation. Furthermore, polymers are lightweight. This attribute makes them perfect for applications where weight is a concern. They are common in the aerospace and automotive industries.

We can recycle many polymers, further reducing waste and conserving resources. Moreover, some polymers are biodegradable, meaning they can break down over time. In that way, we can reduce the amount of waste in landfills.

Key Job Titles

There are many job titles in the polymer industry. Here are some examples:

- Polymer Scientist: Studies the properties and behavior of polymers. They may work in academia or industry. They develop new formulations and test and characterize polymers. Polymer scientists also analyze data.

- Polymer Engineer: Designs and develops polymer products and processes. They may work in the automotive, aerospace, or medical device manufacturing industries. Their work can involve designing and testing new materials and creating production processes. They also troubleshoot problems.

- Polymer Chemist: Specializes in the chemical synthesis and characterization of polymers. They may work in academic or industrial research labs. They design new polymers and develop new polymerization methods. Polymer chemists also characterize polymer properties.

- Polymer Processing Engineer: Designs and optimizes polymer processing operations. They may work in industries such as plastics manufacturing. These engineers design and optimize extrusion, injection molding, or blow molding processes.

- Quality Control Specialist: A professional who ensures that polymer products meet quality standards. They may work in industries such as packaging or medical device manufacturing. They test polymer products for strength, durability, or chemical resistance properties.

- Sales Representative: A sales representative sells polymer products to customers. They may work for a polymer manufacturer or distributor. They develop relationships with customers, negotiate contracts, and provide technical support.

- Production Manager: oversees the creation of polymer products. They may work in industries such as plastics manufacturing. They manage production schedules and coordinate with suppliers and customers. These managers also ensure that production processes meet quality and safety standards.

Why Businesses Need Polymers

Businesses need polymers for many reasons. For example, they are crucial for manufacturing. Manufacturers in many industries use polymers to create their products. They can mold these cheap and versatile materials into various shapes and sizes. Thus, they are ideal for producing everything from plastic toys to medical devices.

Polymers are also great for use in packaging. They are lightweight, durable, and cost-effective. They help to protect products during shipping and storage. It’s easy to design them to be tamper-evident or airtight. These features help to maintain the quality and freshness of the packaged products.

The transportation industry uses polymers to reduce weight and increase fuel efficiency. Auto and airplane parts manufacturers are the best examples of polymer use in this industry. Thus, polymers make transportation more efficient and cost-effective.

Construction is another industry that uses polymers because they are durable and lightweight. They are in everything from insulation to roofing materials. They help to reduce the weight of buildings. Thus, they help to reduce costs and improve energy efficiency.

The healthcare industry uses polymers for a variety of purposes. For example, they are in medical devices and drug delivery systems. Polymers also form part of the packaging for pharmaceuticals. They are biocompatible, which means they do not harm living tissue. Drug makers can use them to release prescriptions over time.

In short, polymers are an essential material for businesses. They have a wide range of properties and applications. They can help to reduce costs and increase efficiency. Polymers also improve the quality and performance of products across many different industries.

Key Success Factors

There are several critical success factors for polymers, including performance. Polymers must have the right combination of properties. Depending on the application, they may need to have mechanical strength or durability. Or they may need thermal stability, electrical conductivity, and chemical resistance.

Polymers need to be cost-effective to produce and use. The cost of production needs to be low enough to make the use of polymers feasible. It’s essential to compare them to other materials before use. Polymers need to be available in enough quantities to meet demand. A reliable supply chain is critical. Businesses must be able to access the polymers they need when they need them.

The environmental impact of polymers is a critical success factor. Businesses must consider the effect of polymer production and use on the environment. They need to take recycling and biodegradability into consideration. Innovation is also critical to the success of polymers. The industry needs to constantly come up with new polymers with improved properties. There’s also a need for ones that can be used in new applications to keep up with changing market demands.

The regulatory environment is also a critical success factor for polymers. Compliance with regulations related to health, safety, and environmental impact is essential. Firms must be compliant to ensure they can continue to operate and meet customer needs.

About Polymer Market Research

SIS International Research offers Quantitative, Qualitative, as well as Strategy Market Research. We also do Market Sizing and UX Market Research. SIS provides Competitive Analysis and Market Entry Research. We can arrange Focus Groups, Surveys, and Interviews to help you form your Go to Market Strategy. Contact us now if you’re looking to enter a new market or make waves in your current one.