Paint, Coating and Adhesives Automation and Artificial Intelligence Consulting

As industries worldwide strive for efficiency and sustainability, the demand for paint, coating and adhesives automation and artificial intelligence consulting has surged, offering unprecedented opportunities for innovation in the paint, coating, and adhesives industry – from enhancing the precision of color matching to optimizing formulations for better performance and lower environmental impact.

What Is Paint, Coating, and Adhesives Automation and Artificial Intelligence Consulting?

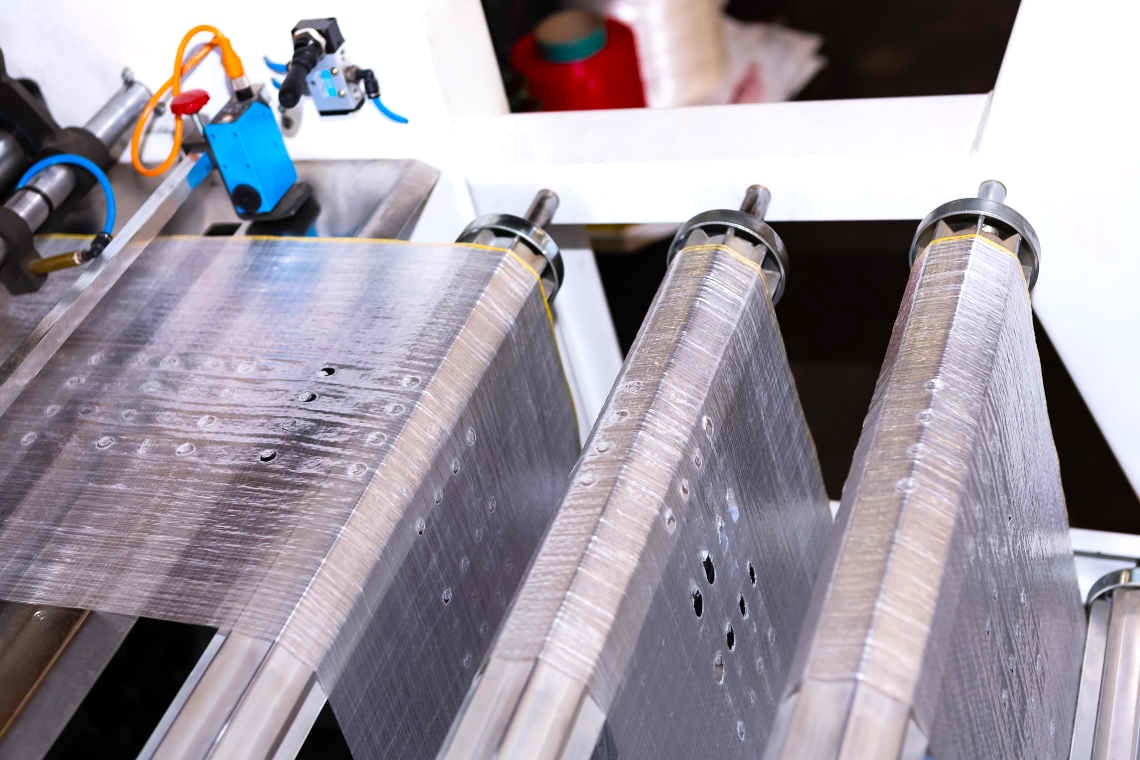

Paint, coating, and adhesives automation and artificial intelligence consulting guides businesses in integrating cutting-edge technologies into their manufacturing processes. This consulting niche leverages automation to streamline production and AI to enhance decision-making, quality control, and operational efficiency. The goal is to transform traditional manufacturing environments into smart, efficient, and sustainable operations that respond dynamically to market changes and customer needs.

At its heart, this consulting involves a comprehensive analysis of existing manufacturing processes to identify opportunities for automation, from raw material handling to the application of coatings and adhesives, and final product packaging. Consultants work closely with businesses to implement robotics, automated machinery, and control systems that increase production speed, reduce waste, and improve product consistency.

Importance of Paint, Coating, and Adhesives Automation and Artificial Intelligence Consulting

Paint, coating and adhesives automation and artificial intelligence consulting enables the analysis of vast amounts of data to identify trends and insights that can lead to the development of new products or the improvement of existing ones. Consulting services help businesses leverage these insights to stay ahead of market demands and regulatory changes.

Moreover, by streamlining production processes and reducing waste, automation and AI can lead to significant cost savings. Consulting identifies these opportunities and helps implement strategies that maximize financial efficiency without compromising quality.

Furthermore, paint, coating and adhesives automation and artificial intelligence consulting services provide expert guidance on selecting and implementing the right technologies that align with the company’s needs and goals. However, this consulting brings many other benefits, including:

- Lepsza jakość produktu: Automation ensures consistent application and quality control in paint, coating, and adhesives manufacturing. AI enhances this by monitoring and adjusting real-time, ensuring products meet stringent quality standards.

- Cost Reduction: Implementing automation and AI can save substantial costs by reducing labor costs, minimizing waste, and optimizing resource use. Paint, coating and adhesives automation and artificial intelligence consulting identifies these opportunities, ensuring that investments in technology deliver a strong return on investment.

- Zrównoważony rozwój: By optimizing material usage and reducing waste, automation and AI contribute to more sustainable manufacturing practices. Paint, coating and adhesives automation and artificial intelligence consulting can guide companies in leveraging these technologies to achieve their environmental goals and respond to increasing consumer demand for eco-friendly products.

- Przewaga konkurencyjna: Companies that successfully integrate automation and AI into their operations can achieve a significant competitive advantage by offering higher quality products at lower costs, responding more quickly to market changes, and driving innovation in their offerings.

Who Uses Paint, Coating, and Adhesives Automation and Artificial Intelligence Consulting

The utilization of paint, coating and adhesives automation and artificial intelligence consulting spans a diverse range of entities such as:

- Manufacturers of Paints and Coatings: These companies engage in consulting to enhance their production processes, improve product quality, and reduce costs. Automation and AI enable them to achieve precise mixing, consistent application, and real-time quality control, ensuring that their products meet the high standards demanded by various industries.

- Adhesives Manufacturers: Entities in the adhesives sector use consulting services to optimize their manufacturing operations, from formulation to packaging. Automation helps achieve high precision in component mixing, while AI can predict the performance of adhesive formulations under different conditions, enhancing product development.

- Automotive Industry Suppliers: Suppliers in the automotive industry, where paints and coatings are critical for aesthetics and protection, seek consulting to integrate advanced automation and AI technologies. This ensures that their products adhere to strict automotive standards, with consulting services guiding the selection and implementation of technologies for efficient, high-quality production.

- Construction and Building Materials Companies: These businesses utilize consulting to automate their paint and coating processes, improving efficiency and sustainability. AI-driven insights help them develop products that meet the evolving needs of the construction industry, such as environmentally friendly and durable options.

- Aerospace and Defense Contractors: In sectors where precision and quality are non-negotiable, such as aerospace and defense, consulting services are crucial. Paint, coating and adhesives automation and artificial intelligence consulting ensure the accurate application of coatings.

- Research and Development (R&D) Facilities: R&D entities focused on developing new materials and formulations for paints, coatings, and adhesives leverage consulting to incorporate automation and AI into their research processes. This accelerates experimentation and analysis, leading to faster innovation cycles.

Expected Results from Our Paint, Coating, and Adhesives Automation and Artificial Intelligence Consulting

Expected Results from Our Paint, Coating, and Adhesives Automation and Artificial Intelligence Consulting

Adopting automation and artificial intelligence in the paint, coating, and adhesives industry, with the guidance of specialized consulting, can lead to a range of transformative outcomes – and here’s what businesses can expect from using paint, coating, and adhesives automation and AI consulting:

- Significant increases in production speed and efficiency, with automation reducing manual labor and AI optimizing processes for minimal downtime and waste.

- Achieving higher levels of product quality and consistency, as automation ensures precise application and mixing, while AI monitors quality in real-time to maintain standards.

- Substantial cost savings through reduced labor requirements, minimized waste, and optimized resource use, leading to improved profitability.

- Accelerated product development and innovation, with AI-driven insights enabling the creation of new formulations and products that meet emerging market needs and regulatory requirements.

- Enhanced sustainability of production processes, as automation and AI contribute to reduced waste and energy consumption, aligning with environmental goals and consumer expectations.

- Increased workplace safety and regulatory compliance, with automation taking over hazardous tasks and AI ensuring processes adhere to industry standards.

- Greater market responsiveness and agility, with AI analytics providing insights into market trends and consumer preferences, allowing for rapid adaptation of production and strategy.

The SIS Approach to Paint, Coating, and Adhesives Automation and Artificial Intelligence Consulting

The SIS International approach to paint, coating, and adhesives automation and artificial intelligence consulting has a deeply client-centric methodology. This approach ensures that clients successfully navigate the integration of these advanced technologies into their operations and leverage them to achieve significant competitive advantages. Here’s how SIS sets itself apart in providing paint, coating and adhesives automation and artificial intelligence consulting:

- Rozwiązania dostosowane do potrzeb: SIS begins with an in-depth analysis of the client’s specific needs, challenges, and strategic goals. This allows for the development of customized automation and AI solutions that align with the business objectives, ensuring that technology investments deliver maximum value.

- Advanced Technology Implementation: With expertise in the latest advancements in automation and AI, SIS advises clients on selecting and implementing the most effective technologies for their specific production processes. This includes robotics, machine learning algorithms, and data analytics tools to enhance efficiency, quality, and innovation.

- Operational Efficiency and Environmental Stewardship: A key component of the SIS approach is enhancing operational efficiency while promoting sustainability. By optimizing production processes and resource use, SIS helps clients reduce waste and energy consumption, contributing to their environmental and sustainability goals.

- Leveraging Data for Strategic Advantage: SIS utilizes data analytics to provide clients with actionable insights into their operations, market trends, and customer preferences. This data-driven approach enables more informed decision-making and strategic planning.

- Łagodzenie ryzyka: Recognizing the importance of risk management, especially in highly regulated industries, SIS incorporates comprehensive risk assessment and management strategies into its consulting services. This ensures clients are prepared for and can mitigate automation and AI integration risks.

- Ongoing Support and Innovation: Beyond initial implementation, SIS offers ongoing support and advice to clients, fostering a culture of continuous improvement and innovation. This long-term partnership approach ensures clients can adapt to evolving market demands and maintain their competitive edge.

- Strategic Vendor Partnerships: SIS assists clients in selecting the right technology vendors and managing these relationships effectively. This ensures clients access the latest technologies and support, maximizing their investment and fostering innovation.