Industrial Automation and Artificial Intelligence Consulting

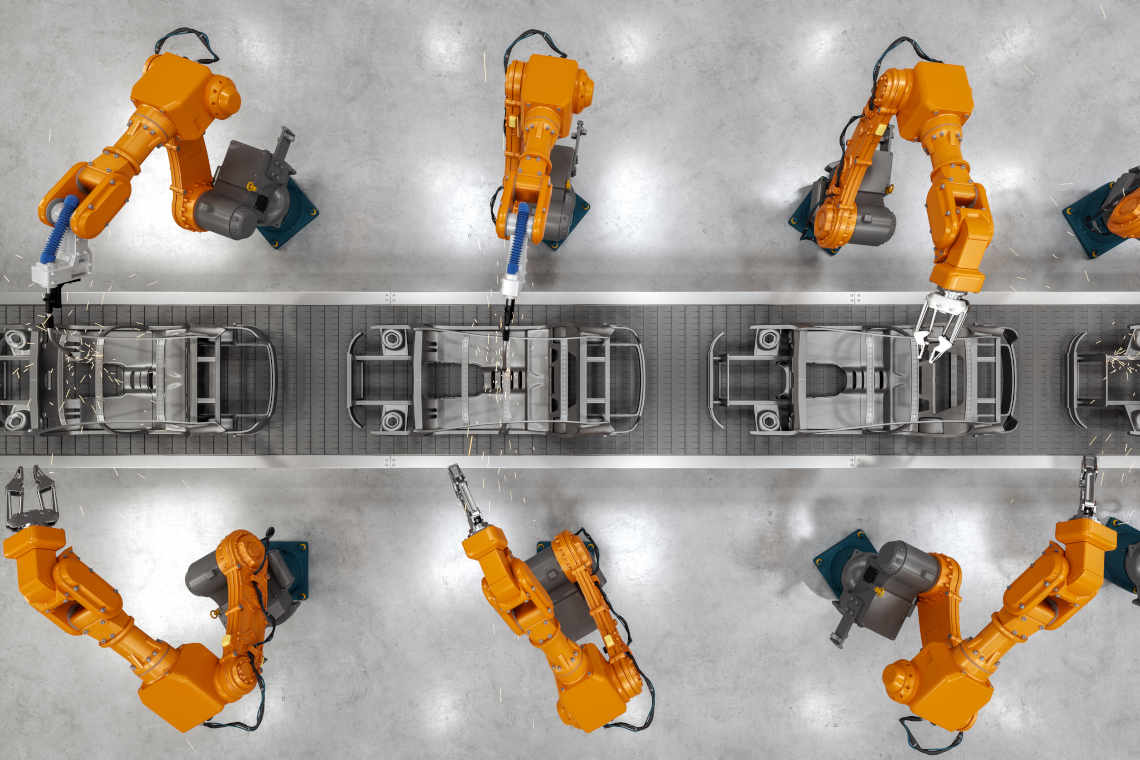

Industrial automation and artificial intelligence consulting is a present-day reality reshaping the landscape of manufacturing and production… And this emerging field stands at the forefront of innovation, merging the precision of automation with artificial intelligence to redefine efficiency, productivity, and creativity in the industrial sector.

Understanding Industrial Automation and Artificial Intelligence Consulting

Industrial automation and artificial intelligence consulting is a field that combines the technical prowess of automation technologies with the cognitive capabilities of AI to revolutionize industrial operations. This consulting service aims to enhance manufacturing and production processes by integrating smart technologies.

On the other hand, the role of consultants is to analyze a business’s specific industrial processes and identify areas where automation and AI can improve efficiency, reduce costs, and increase productivity. This involves a thorough understanding of both the technological aspects and the unique operational characteristics of the business.

What Is the Current Importance of Industrial Automation and Artificial Intelligence Consulting?

The importance of this consulting lies in its ability to transform traditional industrial setups into smart, interconnected systems that can self-optimize. The integration of AI adds a layer of intelligence, allowing systems to predict failures, adapt to new tasks, and continuously improve processes through learning algorithms.

Moreover, industrial automation and artificial intelligence consulting are essential in quality control. AI-driven systems can analyze vast amounts of data to identify patterns that might indicate quality issues, enabling early intervention and thus maintaining high production standards.

Industrial Automation and Artificial Intelligence Consulting: Its Main Benefits

The benefits of industrial automation and artificial intelligence consulting are far-reaching and impact various aspects of industrial operations. Here are some key advantages:

- Cost Reduction: Implementing automation and AI can significantly reduce operational costs. Automated systems work continuously without fatigue, leading to higher output with lower labor costs. AI-driven predictive maintenance can also foresee equipment failures, reducing downtime and maintenance costs.

- Enhanced Quality Control: AI algorithms can analyze data from production processes in real-time, identifying any deviations from quality standards. This immediate feedback allows for quick correction, ensuring consistent product quality and reducing waste.

- Improved Safety: Automating dangerous or repetitive tasks reduces the risk of workplace accidents and exposure to hazardous conditions. AI can further enhance safety by analyzing data to predict and prevent potential safety incidents.

- Sustainability: Automation and AI can optimize the use of resources and energy, leading to more sustainable production processes. This reduces environmental impact and can lead to cost savings and compliance with regulatory standards.

- Competitive Advantage: By adopting advanced automation and AI technologies, businesses can gain a significant competitive edge. They can offer better quality products, respond faster to market changes, and operate more efficiently than competitors who rely on traditional production methods.

How to Conduct Industrial Automation and Artificial Intelligence Consulting

Conducting industrial automation and artificial intelligence consulting is a complex process that requires a strategic approach. Here’s how it can be effectively carried out:

- Initial Assessment and Needs Analysis: The first step involves thoroughly assessing the client’s current industrial processes, identifying areas where automation and AI can improve.

- Strategy Development: This strategy outlines how automation and AI can be integrated into the client’s operations, considering cost, feasibility, and potential return on investment. It’s essential to set clear objectives and measurable outcomes for the project.

- Technology Selection and Customization: This involves selecting appropriate automation hardware and AI software that meet the client’s specific requirements.

- Training and Skill Development: Employees must be trained on new systems and processes to ensure successful adoption. This training should cover operational procedures, safety protocols, and basic troubleshooting.

- System Integration and Testing: The selected automation and AI systems are integrated into the client’s operations. Rigorous testing ensures they function as intended and meet the set objectives.

- Monitoring and Continuous Improvement: After implementation, ongoing monitoring is crucial to track performance and identify areas for improvement. AI systems, in particular, can provide valuable insights over time, which can be used to refine further and optimize processes.

- Feedback and Iteration: Regular feedback from the client and end-users is essential for iterative improvements. This feedback helps fine-tune the systems and make necessary adjustments for better performance and user experience.

Technologies in Industrial Automation and Artificial Intelligence Consulting

The realm of industrial automation and artificial intelligence consulting is underpinned by a diverse array of technologies. Each plays a crucial role in transforming industrial processes. Here’s an overview of the key technologies involved:

- Robotics and Cobots (Collaborative Robots): Robotics are central to industrial automation, performing a range of tasks from assembly to packaging. Cobots, a newer development, work alongside humans, blending the precision of machines with the creativity and problem-solving abilities of humans.

- Computer Vision: This technology allows machines to interpret and act upon visual data. In industrial settings, computer vision is used for quality inspection, defect detection, and guiding robots.

- Big Data Analytics: The vast amounts of data generated in automated and AI-driven processes are analyzed using big data technologies. These insights drive operational improvements and strategic decision-making.

- Digital Twins: A digital twin is a virtual replica of a physical system, used for simulation and analysis. It allows businesses to model and test changes in a virtual environment before implementing them in the real world.

- Additive Manufacturing (3D Printing): This technology is revolutionizing manufacturing, allowing for rapid prototyping, customization, and on-demand production

Opportunities in Industrial Automation and Artificial Intelligence Consulting

Integrating industrial automation and artificial intelligence consulting presents many opportunities for businesses across various sectors. These opportunities enhance operational capabilities and open new avenues for growth and innovation:

- Customized Production: AI and automation enable mass customization, allowing manufacturers to offer personalized products without compromising efficiency. This responds to the growing consumer demand for tailored products.

- Energy Management: AI systems can optimize energy usage in industrial processes, reducing costs and environmental impact. This is particularly relevant in increasing energy prices and the global push toward sustainability.

- Workforce Transformation: While automation may replace specific manual tasks, it also creates opportunities for workforce upskilling. Employees can be trained for higher-level tasks, focusing on system management, optimization, and decision-making.

- Quality Assurance and Compliance: Automated and AI-driven systems provide enhanced capabilities for quality assurance, ensuring products meet the required standards consistently. They also help maintain compliance with regulatory standards.

- Data-Driven Insights and Innovation: The data collected and analyzed through AI can lead to new insights, driving innovation in product development, operational processes, and customer engagement strategies.

SIS Solutions: Industrial Automation and Artificial Intelligence Consulting

SIS uses a comprehensive, integrated approach in Industrial Automation and Artificial Intelligence

We provide strategic insights and solutions to enhance efficiency, productivity, and safety by integrating automation and artificial intelligence in manufacturing and production processes. Our researchers conduct strategic analyses to turn information into actionable insights and help you consider industrial automation and artificial intelligence with a full market view. Our focus on strategic analysis and actionable insights goes beyond data and provides tailored solutions for clients.

- Initial Assessment and Needs Analysis

- Strategy Development

- Technology Selection and Customization

- Implementation Planning

- Training and Skill Development

- System Integration and Testing

- Monitoring and Continuous Improvement

- Feedback and Iteration

Our relationship with industry specialists, generated over the last three decades, allows SIS to go wide and deep into industrial automation and artificial intelligence. The SIS strategy team pulls together the latest in this field, working closely with our local offices abroad.

Our Facility Location in New York

11 E 22nd Street, Floor 2, New York, NY 10010 T: +1(212) 505-6805

About SIS International

SIS International offers Quantitative, Qualitative, and Strategy Research. We provide data, tools, strategies, reports, and insights for decision-making. We also conduct interviews, surveys, focus groups, and other Market Research methods and approaches. Contact us for your next Market Research project.