Manufacturing Automation and Artificial Intelligence Consulting

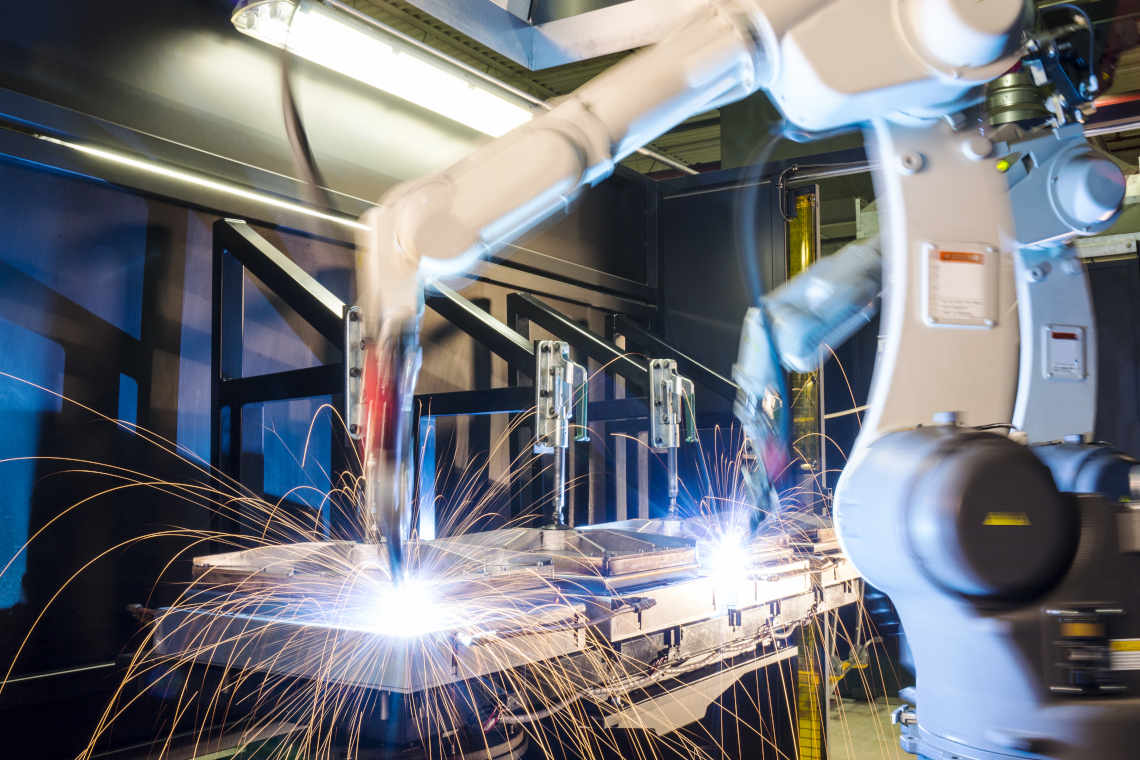

As the manufacturing sector stands at the crossroads of digital transformation, integrating cutting-edge automation and AI technologies is an operational need. Manufacturing automation and artificial intelligence consulting have emerged as a key tool to reshape supply chain management and overall business efficiency.

What is Manufacturing Automation and Artificial Intelligence Consulting?

Manufacturing automation and artificial intelligence consulting focuses on integrating advanced automation and AI technologies into manufacturing processes. Consulting in this field involves assessing a manufacturer’s current processes, identifying areas where automation and AI can bring improvements – and then designing and implementing solutions tailored to the specific needs of the operation.

Why Businesses Need Manufacturing Automation and Artificial Intelligence Consulting

Manufacturing automation and artificial intelligence consulting help businesses set up AI-enhanced quality control systems that can detect defects and issues that might be missed by the human eye, ensuring higher product quality. Automation and AI also enable manufacturers to quickly adjust production lines and processes to meet these changing demands.

Moreover, consulting can contribute to more sustainable manufacturing practices by optimizing resource use, reducing waste, and lowering energy consumption. However, it has many other benefits such as:

- Improved Product Quality and Consistency: Automated systems ensure precision and consistency in manufacturing, leading to higher-quality products. AI-driven quality control can identify defects or variations, ensuring that products meet stringent quality standards.

- Enhanced Scalability: Manufacturing automation and artificial intelligence consulting enable manufacturers to scale their operations up or down more easily, responding effectively to market demands without a corresponding increase in costs or complexity.

- Data-Driven Insights and Decision-Making: The AI aspect of consulting helps manufacturers harness the power of their data. By analyzing data from various sources, AI can provide insights for better decision-making, from predictive maintenance to supply chain optimization.

- Increased Flexibility and Customization: Automation and AI systems allow for greater flexibility in manufacturing processes, making it easier to customize products and quickly adapt to new market trends or customer preferences.

- Enhanced Worker Safety: Automating dangerous or repetitive tasks reduces the risk of accidents and injuries, creating a safer work environment.

Differences Between Manufacturing Automation and Artificial Intelligence Consulting Differ and Traditional Market Research

Traditional market research primarily concentrates on understanding market trends, consumer behaviors, and preferences. In contrast, manufacturing automation and artificial intelligence consulting focus on enhancing manufacturing processes through technology. It involves the application of AI and automation to improve efficiency, productivity, and innovation in manufacturing operations.

While traditional market research utilizes data to understand external market dynamics and consumer sentiments, manufacturing automation and artificial intelligence consulting leverage data for internal process optimization. Manufacturing automation and artificial intelligence consulting tend to have a more direct and long-term strategic impact on the business’s core operations. They improve current manufacturing processes and also sets the stage for ongoing innovation and adaptation to future technological advancements.

Key Success Factors in Manufacturing Automation and Artificial Intelligence Consulting

Businesses must meet certain criteria to successfully engage in manufacturing automation and artificial intelligence consulting. These factors are essential in ensuring the effective implementation and optimization of these technologies in manufacturing.

- Robust Data Infrastructure: The foundation of effective AI applications in manufacturing is robust data infrastructure. Accurate, comprehensive, and real-time data collection and management systems are crucial for AI algorithms to function effectively and deliver valuable insights.

- Selection of Appropriate Technologies: Identifying and choosing the right automation and AI technologies that fit the specific needs of the manufacturing process is crucial.

- Employee Engagement and Training: Successful implementation requires the engagement and training of employees. Workers must be educated on the new technologies, how they will impact their roles, and the benefits they bring to ensure smooth adoption and operation.

- Risk Management and Compliance: Ensuring that the automation and AI solutions comply with relevant regulations and standards, especially regarding safety and data security, is essential.

- Measuring ROI and Impact: Regularly measuring the return on investment (ROI) and the overall impact of automation and AI on manufacturing operations is crucial to understanding their effectiveness and guiding future technology decisions.

What Are the Expected Results from Manufacturing Automation and Artificial Intelligence Consulting?

Engaging in consulting yields significant results in manufacturing operations, driving growth, and maintaining a competitive advantage – and some of the most important expected outcomes are:

- Enhanced Product Quality: Automated systems provide consistent and precise manufacturing outputs, significantly improving product quality. AI-enabled quality control systems can detect and correct flaws, ensuring high-quality standards.

- Cost Reduction: Automation reduces labor costs associated with manual tasks and minimizes errors that could lead to costly rework. AI-driven process optimizations also contribute to cost savings by reducing waste and improving energy efficiency.

- Data-Driven Operational Insights: AI’s ability to analyze vast amounts of operational data leads to deeper insights, enabling more informed decision-making in predictive maintenance, supply chain management, and production planning.

- Greater Flexibility and Scalability: Automation and AI provide the flexibility to quickly adapt production processes to changing market demands. They also allow for scalability, enabling manufacturers to increase production without proportionately growing costs.

- Reduced Downtime: AI-powered predictive maintenance reduces unplanned downtime by foreseeing equipment failures and scheduling timely maintenance.

Technologies and Tools in Manufacturing Automation and Artificial Intelligence Consulting

The field of manufacturing automation and artificial intelligence consulting leverages a wide array of technologies and tools. These are essential in transforming traditional manufacturing processes into advanced, efficient systems.

- Machine Learning Platforms: TensorFlow and PyTorch are used to develop custom AI models that can predict equipment failures, optimize production schedules, and enhance quality control.

- IoT Platforms: Siemens MindSphere and GE Predix collect and analyze data from connected devices to monitor and optimize manufacturing processes.

- AI Optimization Software: Tools such as Google AI Platform help optimize various aspects of manufacturing, from resource allocation to energy consumption.

- 3D Printing Technologies: 3D printing, or additive manufacturing, from companies like Stratasys and 3D Systems, is increasingly integrated into manufacturing for rapid prototyping and production.

- Edge Computing Solutions: Technologies from companies like Cisco facilitate edge computing in manufacturing environments, enabling faster processing and decision-making at the data collection site.

Opportunities in Manufacturing Automation and Artificial Intelligence Consulting

The integration of automation and artificial intelligence in manufacturing opens up a wealth of opportunities for businesses in this sector. These opportunities enhance operational efficiencies and pave the way for innovative approaches to manufacturing challenges.

- Energy and Resource Efficiency: AI can optimize the use of resources, including raw materials and energy, contributing to more sustainable and cost-effective manufacturing processes.

- Worker Safety and Ergonomics: Automation takes over hazardous tasks, reducing workplace accidents, and improving overall worker safety and ergonomics.

- Market Responsiveness: With automation and AI, manufacturers can swiftly respond to market changes, adapting production lines and processes quickly to new trends or demands.

- R&D and Product Development: AI-driven insights can inform research and development efforts, leading to innovative product designs and improvements.

- Global Competitiveness: Manufacturing automation and artificial intelligence consulting can help manufacturers compete globally, improving both cost efficiency and product quality, which are critical factors in international markets.

SIS Solutions: Manufacturing Automation and Artificial Intelligence Consulting

We provide strategic insights and AI solutions to revolutionize manufacturing processes, ensuring higher product quality, operational efficiency, and sustainability. Our approach to strategic analysis and actionable insights helps clients harness the power of AI and automation for enhanced scalability, data-driven decision-making, and worker safety. Solutions include robust data infrastructure, selection of appropriate technologies, employee training, risk management, and measuring ROI.

- Data Infrastructure Development

- Technology Selection and Integration

- Employee Engagement and Training Programs

- Compliance and Risk Management Strategies

- ROI and Impact Measurement Systems

- Operational Insights and Predictive Maintenance

- Scalability and Flexibility Enhancement

Our extensive industry network enables SIS to provide comprehensive insights into manufacturing automation, supported by our global team’s latest methodologies and technologies.

Our Facility Location in New York

11 E 22nd Street, Floor 2, New York, NY 10010 T: +1(212) 505-6805

About SIS International

SIS International offers Quantitative, Qualitative, and Strategy Research. We provide data, tools, strategies, reports, and insights for decision-making. We also conduct interviews, surveys, focus groups, and other Market Research methods and approaches. Contact us for your next Market Research project.