機械自動化與人工智慧諮詢

The powerful synergy between machinery automation and artificial intelligence consulting is creating more efficient and adaptive systems than ever–redefining the nature of manufacturing, production, and other machinery-intensive sectors.

The Critical Role of Machinery Automation and Artificial Intelligence Consulting

Machinery automation and artificial intelligence consulting focus on strategically implementing AI technologies and automated systems in industrial machinery and production processes. This service enhances the efficiency, safety, and productivity of manufacturing operations. It includes integrating robotics, sensor technology, and advanced data analytics into machinery to automate routine tasks, optimize production workflows, and facilitate predictive maintenance.

But… Why Is It Important?

Machinery automation and artificial intelligence consulting allow companies to quickly adapt their production processes to changing market needs, enabling them to respond swiftly to new opportunities or challenges. Moreover, AI-driven machinery automation allows for greater customization in production processes. This means products can be tailored to meet specific customer requirements more efficiently, enhancing customer satisfaction and opening new market opportunities.

Additionally, the integration of AI in machinery automation enables the collection and analysis of vast amounts of data. This data-driven approach leads to more informed decision-making, optimizing operations, reducing waste, and identifying areas for improvement.

When to Seek Machinery Automation and Artificial Intelligence Consulting Services

Determining the optimal time to conduct machinery automation and artificial intelligence consulting is crucial for maximizing its benefits and ensuring a strategic alignment with business goals. Therefore, some key scenarios and indicators suggest it’s the right time for a company to consider these advanced technological integrations.

- 營運效率的需求: If a company struggles with inefficiencies, high operational costs, or quality control issues, machinery automation and artificial intelligence consulting can provide effective solutions.

- Technological Advances in the Industry: When new automation technologies or AI advancements become available, assessing their potential impact and applicability can keep a company technologically relevant.

- Sustainability and Regulatory Compliance: For companies looking to improve their sustainability practices or needing to comply with new regulatory requirements, machinery automation and artificial intelligence consulting can offer practical solutions. These technologies can optimize resource usage and ensure environmental and safety regulations compliance.

- Workforce Limitations: In situations where there is a shortage of skilled labor or where tasks are too hazardous for human workers, automation becomes a necessity. AI and robotics can fill these gaps, ensuring continuous and safe operations.

How Does Machinery Automation and Artificial Intelligence Consulting Differ from Traditional Market Research?

Traditional market research gathers insights about consumer preferences, market needs, and competitive landscapes. In contrast, machinery automation and artificial intelligence consulting focus on optimizing production processes, improving machinery efficiency, and leveraging data for operational decision-making.

Similarly, traditional market research typically does not involve the direct implementation of technology in operational processes. On the other hand, machinery automation and AI consulting are deeply rooted in the technological transformation of machinery and processes, involving the integration of AI, machine learning, and robotics.

Lastly, the outcomes of traditional market research are insights that inform marketing strategies and product development. In machinery automation and artificial intelligence consulting, the outcomes are more tangible regarding improved machinery performance, increased production efficiency, and reduced operational costs.

What Kind of Results Does Machinery Automation and Artificial Intelligence Consulting Deliver?

Machinery automation and artificial intelligence consulting deliver a wide array of benefits and that significantly impact various aspects of industrial operations. By integrating these advanced technologies, businesses can expect to see tangible improvements in several key areas such as:

- Increased Production Efficiency: One of the most immediate and significant impacts is improved production efficiency. Automated machinery can operate faster, with greater precision, and more extended periods, leading to a substantial boost in output and productivity.

- Enhanced Product Quality and Consistency: AI systems can monitor and adjust production processes in real-time, ensuring that each product meets quality standards.

- Improved Workplace Safety: Automated machinery can take over hazardous tasks and operate in dangerous environments, reducing the risk of workplace accidents and enhancing overall safety.

- Optimized Resource Utilization: AI can optimize the use of materials and energy, leading to more sustainable and cost-effective operations. This optimization is increasingly important where resource efficiency and sustainability are critical business considerations.

- 競爭優勢: Businesses that successfully integrate machinery automation and AI can gain a significant competitive advantage. They can offer better products at lower costs, respond more quickly to market demands, and lead innovation.

Current Trends in Machinery Automation and Artificial Intelligence Consulting

The field of machinery automation and artificial intelligence consulting is driven by technological advancements. Thus, staying abreast of current trends is crucial for businesses to leverage these technologies effectively – and here are some of the prominent trends shaping this dynamic field:

- Integration of the Internet of Things (IoT) and AI: The growing integration of IoT with AI is a significant trend. IoT devices in industrial settings generate vast amounts of data, and AI is used to analyze this data for insights into machine performance, predictive maintenance, and operational efficiencies.

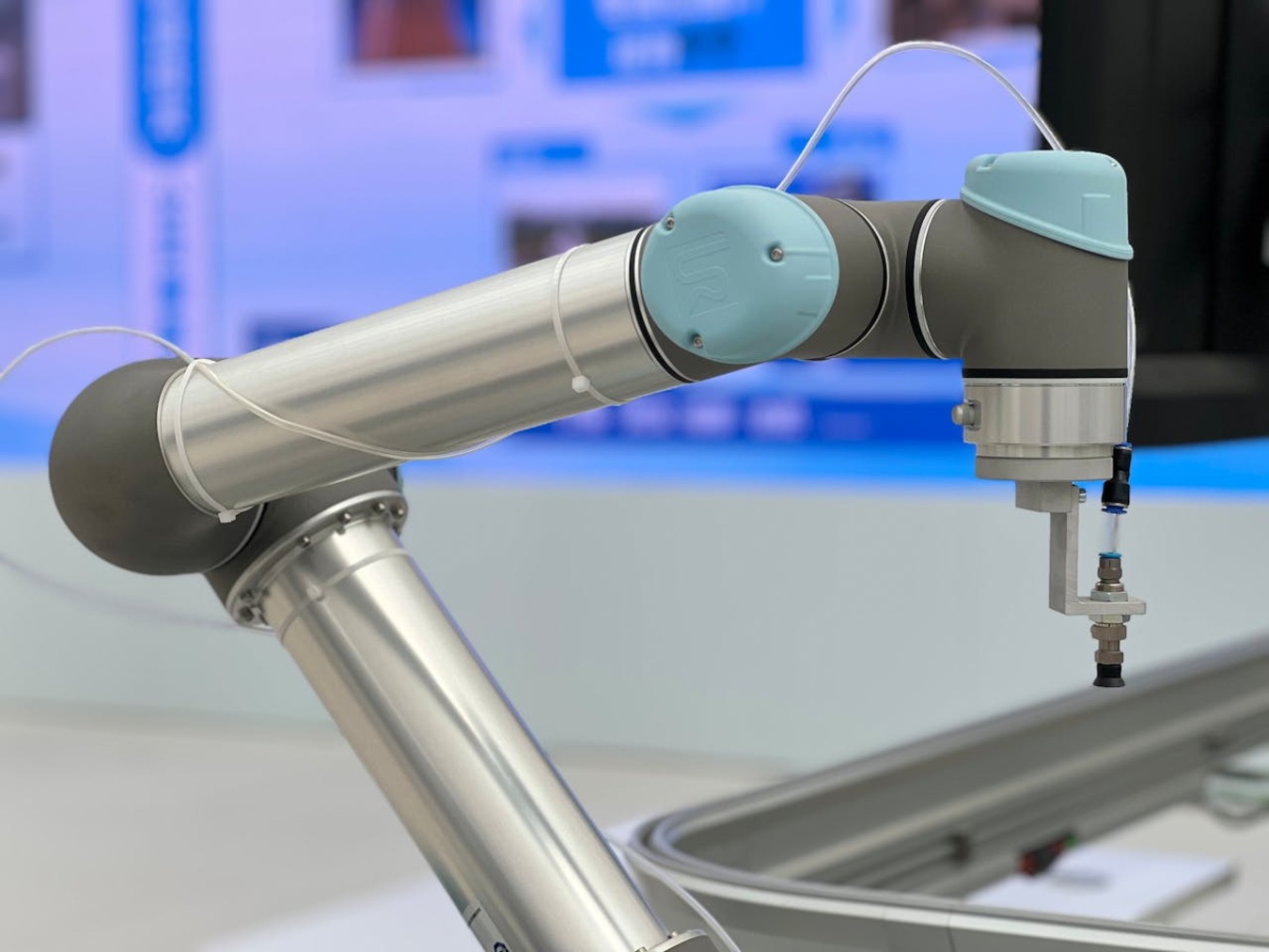

- Increased Use of Collaborative Robots (Cobots): Cobots are designed to work alongside human workers, enhancing safety and efficiency. They are increasingly being integrated into manufacturing processes, combining machines’ precision and consistency with humans’ problem-solving capabilities.

- Focus on Energy Efficiency and Sustainability: There’s a growing emphasis on using AI to optimize energy consumption and reduce the environmental impact of industrial operations. AI algorithms monitor and adjust energy usage, contributing to more sustainable practices.

- Custom AI Solutions for Specific Industry Needs: There is a move toward developing custom AI solutions tailored to the specific needs of different industries. These solutions ensure that the unique challenges and requirements of each sector are addressed more effectively.

- Enhanced Human-Machine Interfaces: Human-Machine Interfaces are becoming more intuitive and user-friendly, making it easier for workers to interact with automated systems and AI tools. This improves efficiency and reduces the learning curve associated with new technologies.

Opportunities and Challenges in Machinery Automation and Artificial Intelligence Consulting

Integrating machinery automation and artificial intelligence consulting in industrial settings presents a blend of exciting opportunities and challenges… That’s why understanding and navigating these can help businesses maximize the benefits while mitigating potential drawbacks.

機會

- 提高營運效率: Automation and AI significantly enhance operational efficiency, allowing for faster production times, reduced errors, and increased output.

- 降低成本: Over time, the investment in automation and AI can lead to substantial cost savings in labor, maintenance, and operational expenses.

- 數據驅動的決策洞察: The ability of AI to analyze large datasets provides valuable insights for strategic decision-making, helping businesses to stay ahead of market trends.

挑戰

- 與現有系統整合: Integrating new technologies with existing machinery and systems can be complex and time-consuming.

- 網路安全風險: Increased reliance on digital systems raises the risk of cybersecurity threats, necessitating robust security measures.

- Maintaining and Upgrading Technology: Keeping up with rapidly advancing technology requires continuous updates and maintenance, which can be costly and resource-intensive.

SIS Solutions: Machinery Automation and Artificial Intelligence Consulting

We provide comprehensive solutions that enhance operational efficiency, safety, and productivity in manufacturing through the strategic implementation of AI and automated systems. Our researchers conduct strategic analyses to offer actionable insights, helping clients navigate machinery automation and artificial intelligence with a full market perspective. Our services include:

- Integration of robotics and sensor technology

- Advanced data analytics for operational optimization

- Predictive maintenance facilitation

- Custom AI solutions tailored to industry-specific needs

- Enhanced human-machine interfaces for intuitive interaction

- Collaborative robots (Cobots) integration

- Sustainable and energy-efficient operation strategies

Our extensive experience and relationship with industry specialists enable SIS to offer deep insights into machinery automation and artificial intelligence. We stay at the forefront of technology, working closely with our global offices to deliver tailored solutions.

我們在紐約的工廠位置

11 E 22nd Street, Floor 2, 紐約, NY 10010 電話:+1(212) 505-6805

關於 SIS 國際

SIS國際 提供定量、定性和策略研究。我們為決策提供數據、工具、策略、報告和見解。我們也進行訪談、調查、焦點小組和其他市場研究方法和途徑。 聯絡我們 為您的下一個市場研究項目。